Case Detail

Scanning Rangefinder

Safety measurement for Rubber manufacturer / Conveyor

Safety measurement for Rubber manufacturer / Conveyor

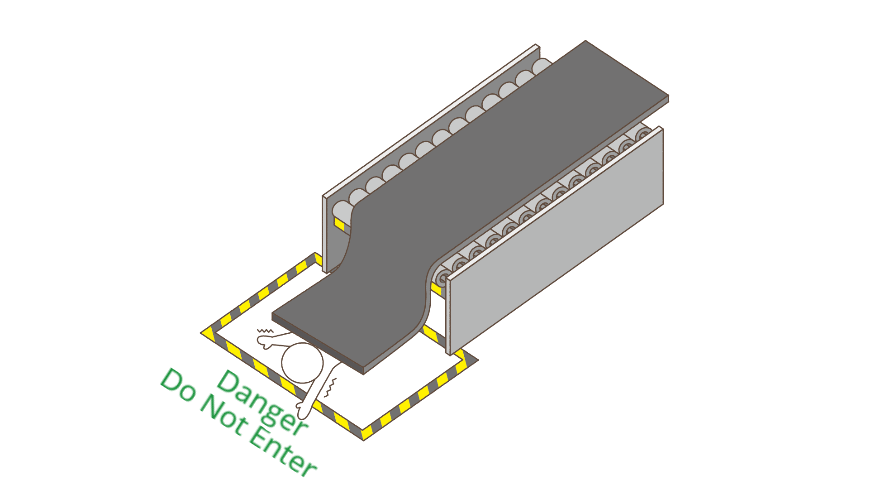

An accident occurred at a material retention area, and a worker was crushed by a rubber sheet flowing from a conveyor.

There was a stagnation area next to the aisle and “No trespassing" signs were posted. However, fences were not installed there in order to improve work efficiency during material transportation.

There was a stagnation area next to the aisle and “No trespassing" signs were posted. However, fences were not installed there in order to improve work efficiency during material transportation.

Case Study

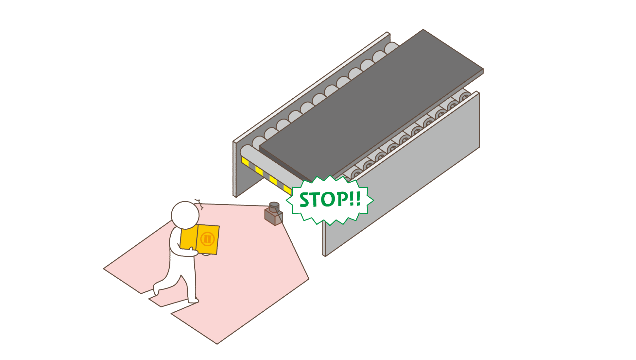

It is used to detect the presence of workers, and it stops the conveyor when workers are in the danger area.

Light curtain was installed there once, but the optical axis misalignment was occurred often, so it was replaced to LiDAR at the end.

LiDAR is installed under the conveyor, and the detection area is set easily and flexibly. The area is set as avoiding the aisle, so the material transportation works efficiently.

Optical axis misalignment is never occurred because LiDAR is a reflective type sensor. Maintenance becomes easier and safety measures successfully progresses.

Product's Category

- Scanning Rangefinder

- Photoelectric Switch

- Sensor for Iron & Steel Industry

- Optical Data Transmission Device