About Us

Who we are

HOKUYO, founded in Osaka, Japan in 1946, developed and continues to offer some of the original automation technology with products such as counters, photoelectric sensors and Automatic doors for a wide range of factory automation systems and various production processes.

For many years we have been developing several types of products for factory automation that include high-accuracy CCD sensors and optical data transmission devices and maintain an outstanding reputation for our creativity and performance with customers.

HOKUYO products are integrated into many industrial sectors such as textiles, electric wire, iron & steel, transportation systems, mounting machines, semiconductor and LCD facilities. They have contributed to the growth and development of these industries.

With the fast-paced changes in information technology, industrial globalization and despite the environmental and safety uncertainties we face in the world today, Hokuyo will adapt and continue to thrive as a leader and continue to pursue its growth with great efficiency.

As a pioneer of automation technology, Hokuyo will be sensitive and proactive to the needs of customers and pursue the challenges ahead to offer the best product solutions in the future.

Hokuyo looks forward to your continued business in the future.

Our Policy

Before the word “automation” became well-known, we began dealing with automatic control, satisfying our customer's needs and producing original products that helped many industrial fields.

Our basic policy is to always comply with social standards and changing values, consistently develop a steady and distinctive management upon our foundation of self-improvement, fulfill the satisfaction of our customers, and continue growing as a company.

Corporate Profile

| Company name | HOKUYO AUTOMATIC CO., LTD. |

|---|---|

| President | Hitoshi Ozaki |

| Head office | Higobashi Union Building, 1-9-6 Edobori, Nishi-ku Osaka-shi, Osaka 550-0002 Japan |

| Establishment | April 8, 1946 |

| Capital | 50 million JPY |

| Employees | 240 |

Products

-

Sensors

-

- Photoelectric switch

- Laser type

- Microwave type

- Ultrasonic type

- Laser Distance Sensor

-

Optical Data Transmission Devices

-

- Serial type

- Parallel type

- Optical Remote Controller

-

Obstacle Detection Sensors

-

- For AGV

- For Robotics

- Close Crane Warning Device

Quality Management Efforts

-

Quality Policy

-

Our quality policy is to "continue our efforts to develop original technologies and products and to implement a quality management system in order to provide customers all over the globe with products that offer excellent functionality and quality, and fulfill our social roles while aiming for continuous growth between the company and all participants". We created a quality management system compliant with ISO9001 and obtained certification in 1997 (upgraded to ISO9001:2015 in 2018).

-

Quality Efforts

-

-

In order to "provide customers all over the globe with products that offer excellent functionality and quality" as stated in our quality policy, we obtained ISO9001 certification for international quality management systems. We continue to improve this system to ensure the satisfaction of our customers, and continue our efforts daily to stabilize quality and provide even greater products to our customers.

-

In order to fulfill our corporate social role, we aim to develop products in an environmentally-conscious manner, while naturally complying with laws, regulations, and requirements.

-

Environment Efforts

-

Environmental Policy

-

Based on our environmental principle of "contributing to society through developing automatic control devices and automatic doors in harmony with abundant global environments, and striving to continue to be trusted by local societies, customers, employees, and other stakeholders", we have set the following environmental policy, built an environmental management system compliant with ISO14001, and obtained certification in March 2004 (upgraded to ISO14001:2015 in 2018).

-

We objectively determine the impact of all our business practices on the environment to the degree that this is possible, set improvement goals and objectives, and promote environmental practices.

-

We maintain and continuously improve our environmental system, and strive to prevent possible contamination.

-

We comply with arrangements and agreements related to environmental laws, respect voluntary standards created by affiliated organizations and industry groups, and actively participate and cooperate in environmental conservation activities conducted at the national and local levels.

-

In order to promote and implement our environmental policy, we set improvement goals and objectives each fiscal year for the company as a whole and for each individual division, evaluate our results, and revise our policy.

-

In addition to spreading awareness among all workers to ensure that this environmental policy is implemented and maintained, we also disclose our policy to subcontractors and require that they comply with it. We also disclose our policy in our company profile and on our company website.

-

-

Environmental Efforts

-

-

In order to provide customers with environmentally-conscious products, we have obtained ISO14001 certification for international environmental management systems. We also continue to improve our system out of concern for the environment.

-

We develop products and propose automatic control systems in an environmentally-conscious manner, and aim to realize a reduced energy society through the customers who use our products.

Examples of Energy Saving by Using Our Products

Head-count and mobility measurement by the scanning range finder (SOKUIKI sensor)

Information on the number of people and where they are moving is obtained within a certain preset area so that air conditioning and lighting can be controlled based on the number of people in the area, and allowing doors to be opened and closed when required.

Information on the number of people and where they are moving is obtained within a certain preset area so that air conditioning and lighting can be controlled based on the number of people in the area, and allowing doors to be opened and closed when required.

UST-10LX/20LX UTM-30LX-EWFactory Automation

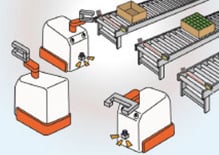

Factory automation makes it possible to realize the shortening of hours, energy savings through efficiency in the process and a decrease of CO2 emissions.

Factory automation makes it possible to realize the shortening of hours, energy savings through efficiency in the process and a decrease of CO2 emissions.

In addition, a reduction of human errors through automation leads to yield improvement and a lower level of defectiveness, thus making it possible to eliminate waste of resources and energy.

UST-05LN/LAAutomation in Our Daily Life

Daily life continues to be automated, as seen in robots that aid shoppers and help with daily life as well as home and commercial facility automation. We provide ”Optics” for these automation solutions and help create the environments necessary for automation to function.

Daily life continues to be automated, as seen in robots that aid shoppers and help with daily life as well as home and commercial facility automation. We provide ”Optics” for these automation solutions and help create the environments necessary for automation to function.

UST-10LX/20LX UTM-30LX-EW -

We promotes in response to RoHS Directive and promotes green procurement in order to realize earth-conscious products as a corporation.

【Response to the RoHS Directive】

Control devices are classified as Category 9 products under the RoHS Directive.

We continue our efforts to remain compliant with the latest RoHS Directive.

Please contact our sales department or contact us through our website for information on products compliant with the RoHS Directive.

*The effective date of RoHS Directive revisions varies by category.【Green Procurement】

Our green procurement means investigating the constituents of components in our products and content of regulated substances along with prohibiting and managing the object substances based on the guidelines formulated.

-

Hokuyo aims to make our workplace an energy-saving factory.

Reduced power usage through more efficient air conditioning units

We reduced power usage through more efficient air conditioning units and by covering the roof of the production building with a moss greening unit and light-blocking sheet.

We reduced power usage through more efficient air conditioning units and by covering the roof of the production building with a moss greening unit and light-blocking sheet.< An important note for suppliers about purchased parts >

As an effort to reduce our burden on the environment and comply with customer requests and legal regulations, we inspect purchased parts for controlled substances and HOKUYO regulated substances. Our inspection forms are based on "chemSHERPA" as stipulated by the Joint Article Management Promotion-consortium.

Minerals produced in conflict areas carry the risk of being used as sources of funds for local armed organizations, or organizations involved in illegal activities such as human rights violations, environmental destruction, or corruption. In response to the issue of these so-called "conflict minerals", we are involved in investigating where raw materials are produced and by whom they are refined, in order to fulfill our social duties when procuring parts. We ask for you cooperation if contacted by a member of our staff regarding this issue.

-

International Organization for Standardization

-

ISO9001 / JQA-1742

Quality management system ISO9001, obtained in May 1997.

-

ISO14001 JQA-EM3873

Obtained International Standard “ISO14001” for Environment Management System in March 2004.

Company History

| 1946 | HOKUYO ELECTRIC CO., LTD. founded at 8 Banchi, Eiraku-cho, Kiata-ku, Osaka City with JPY 180,000 in capital with 10 employees. Began sales of electronics, mainly automatic control devices. |

|---|---|

| 1948 | Increase in capital to JPY 1 million. |

| 1949 | Changed corporate name from HOKUYO INDUSTRY CO., LTD to HOKUYO AUTOMATIC CO., LTD. |

| 1951 | Set up Juso factory in Higashi-yodogawa-ku, Osaka city. Began to produce a cshion starter and counter. |

| 1954 | First photoelectric sensor completed. Delivered to Daiwabo Co., Ltd. Prototype of an electric Automatic door completed. |

| 1955 | Set up Tokyo office. Began to produce an air type reset counter. |

| 1956 | Began to sell Automatic doors. | 1957 | Developed a timer and counter-timer. |

| 1958 | Beginning with digital counters, developed products such as micro timers, sequence timers, and printing counters. Developed an automatic reset counter by motor. |

| 1959 | Set up Nagoya office. Increase in capital to JPY 10 million. Began to sell micro timers. |

| 1961 | Increase in capital to JPY 20 million. |

| 1963 | Increase in capital to JPY 50 million. Developed a 3-shift counter and hot metal detector. |

| 1964 | Moved Head Office to Sonezaki, Kita-ku, Osaka city. Began company-wide total quality management. |

| 1965 | Set up Kyushu office. |

| 1967 | Set up Mikuni factory in Niitaka, Yodogawa-ku, Osaka city. |

| 1970 | Began to sell electronic counters. |

| 1972 | Began to sell a microwave sensor. |

| 1974 | Began to sell a laser sensor. |

| 1977 | Set up Shizuoka office. Began to sell an ultraviolet sensor. |

| 1979 | Demands for microcomputer equipped devices increase. Continuous development of system devices. Developed compact photoelectric sensors, optical data trancemission devices, and pattern inspection devices. |

| 1980 | Began to sell a fiber type sensor and elctronic counter with nonvolatile memory. |

| 1981 | Began to sell a 10 micron type optical contour measuring sensor. |

| 1982 | Began to sell a fiber type sensor with 2-beam and area sensor. |

| 1984 | Began to sell a LCD type electronic counter, optical character reading sensor and 1 micron type optical contour measuring sensor. |

| 1987 | Began to sell a proximity sensor. |

| 1988 | Began to sell an optical remote controller. |

| 1994 | Began to sell an electronic counter with communicating function. |

| 1995 | Began to sell an image-recognition sensor. |

| 1996 | Began to sell an automatic tuning type fiber sensor. |

| 1997 | Released an image sensor displacement gauge, LED linear length measuring sensor and optical distance sensor. Obtained international standard ISO9001. |

| 2001 | Began to sell an obstacle detection sensor. |

| 2004 | Obtained international standard ISO14001. Began to sell a laser range finder. |

| 2005 | Numerous laser range finders get equipped in robots of Expo 2005 Aichi Japan. |

| 2006 | Laser range finder awarded 2006 This Year's Robot Awards award for excellence. |

| 2007 | Selected as one of best 300 companies in small-medium companies. Participated Tsukuba Challenge (Real World Robot Challenge). |

| 2008 | Moved Head Office to Tokiwamachi, Chuo-ku, Osaka city. |

| 2009 | Laser range finder awarded 2008 Japan Society of Mechanical Engineers Award-Technolory. |

| 2010 | Subsidiary Company in South Korea, HOKUYO KOREA CO., LTD. established. |

| 2011 | Toyonaka Factory established in Toyonaka City, Osaka Prefecture. |

| 2016 | Aquired all of the outstanding shares of its long-term distributor Sentek Solutions, Inc. and changed the name to Hokuyo Automatic USA Corporation as wholly owned U.S. subsidiary, started the operation. Established Amsterdam office as a branch of International Sales Department. |

| 2018 | Moved Head Office to Edobori, Nishi-ku, Osaka city. |

| 2023 | Subsidiary Company in P.R. China, HOKUYO AUTOMATIC (SHANGHAI) CO., LTD. (北阳好酷优自动化设备(上海)有限公司) established. |

- Scanning Rangefinder

- Photoelectric Switch

- Sensor for Iron & Steel Industry

- Optical Data Transmission Device